Nanostone Launches CUF|ShieldPlus™ to Solve Semiconductor Industry’s Toughest Wastewater Challenges

Nanostone launches CUF|ShieldPlus™, a ceramic ultrafiltration module for toughest semiconductor wastewater challenges. Debuting at SEMICON SEA 2025.

May 19, 2025

New ceramic ultrafiltration module engineered for the most demanding industrial water conditions, debuting at SEMICON Southeast Asia 2025 in Singapore

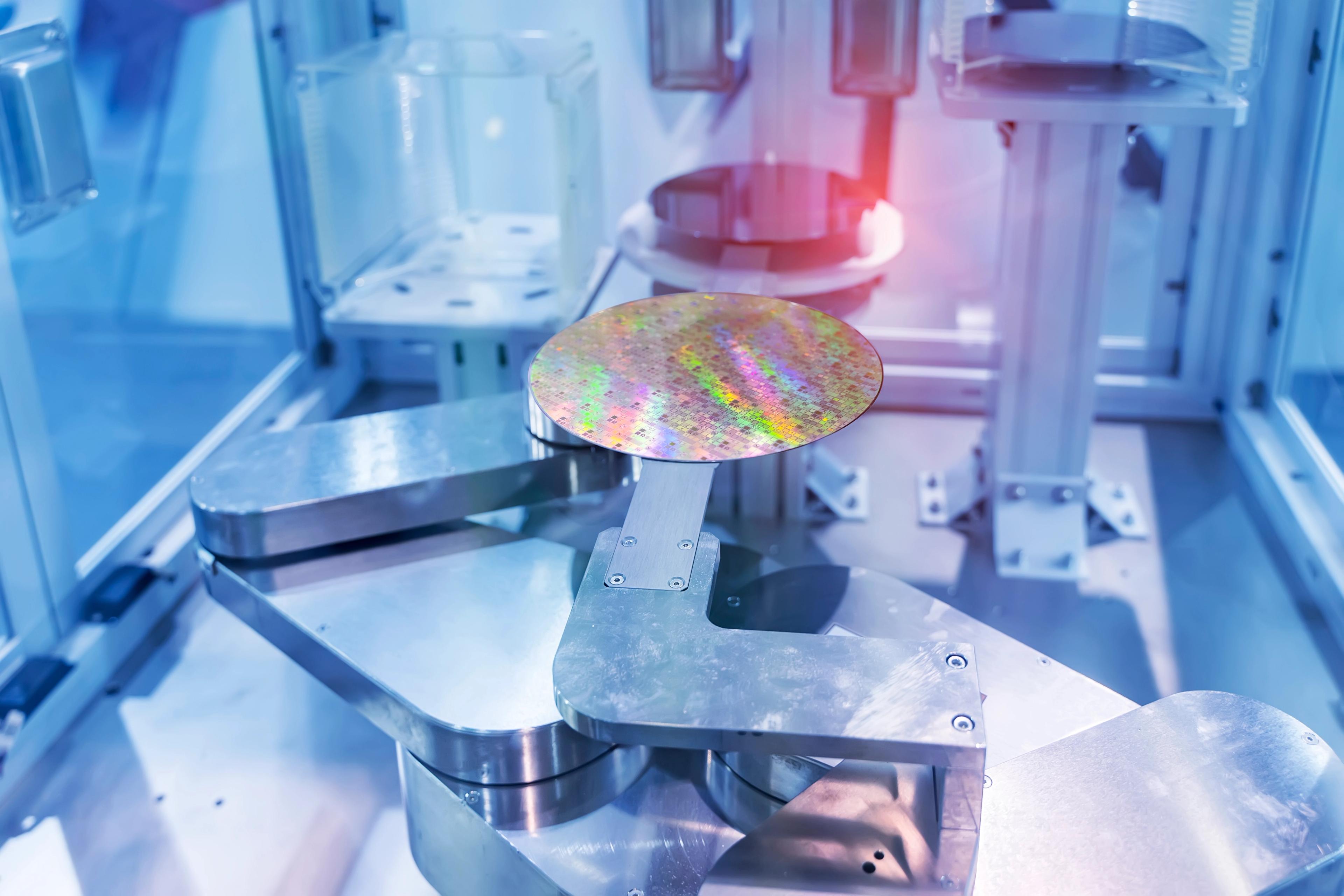

Boston, MA — May 19, 2025 — Nanostone Water today announced the launch of CUF|ShieldPlus™, its new precision ceramic ultrafiltration solution for the most demanding industrial water applications. Designed for specialized, mission-critical industrial water infrastructure, CUF|ShieldPlus™ handles extreme fouling, chemical variability, and high particulate loads. The product will make its global debut at SEMICON Southeast Asia 2025, taking place May 20–22 in Singapore.

Developed to address the challenging wastewater streams in Semiconductor Manufacturing, CUF|ShieldPlus™ is also positioned to meet similarly complex treatment demands in the Food & Beverage and Pharmaceutical industries where hygiene, consistency, and water recovery are tightly regulated and operationally critical.

“We’ve seen that some of the world’s fastest-growing industries are also facing the toughest wastewater challenges,” said Jürgen von Hollen, CEO of Nanostone Water. “The semiconductor and microelectronics sectors generate some of the most complex wastewater streams, many of which can now be effectively addressed with our new CUF|ShieldPlus™ module. We’re helping customers turn these challenging wastewater streams into opportunities for high-value reuse, delivering a scalable, field-proven solution that not only strengthens compliance and reduces risk, but also supports long-term sustainability and growth targets for our customers.”

Built for Process-Critical Wastewater

In semiconductor facilities, Grinding & Cutting, Chemical Mechanical Planarization (CMP), and Hydrofluoric Acid (HF) streams account for more than 50% of total wastewater volume and carry the greatest regulatory, operational, and technical complexity. CUF|ShieldPlus™ is designed to deliver in these conditions. It offers:

- Long membrane life in high-solid, corrosive environments

- Stable performance under pH swings, organic fouling, and metal loading

- Low SDI permeate to protect downstream RO systems

- A modular footprint for integration near the source or within existing treatment trains

Proven Platform, Broader Reach

Nanostone’s ceramic membrane technology is currently deployed in over 40 semiconductor sites worldwide. CUF|ShieldPlus™ builds on this foundation with precision chemical resistance, durability, and fouling tolerance. It complements the company’s CUF|Shield™ platform, already used in a broad range of industrial and municipal applications, from cooling tower blowdown and boiler systems, seawater desalination to drinking water applications.

“CUF|ShieldPlus™ is our answer to the most challenging industrial water problems, such as semiconductor and microelectronic applications” von Hollen added. “But the CUF|ShieldPlus™ performance characteristics make it equally suited for critical water reuse and recovery applications in food, beverage, and pharmaceutical manufacturing.”

Launching at SEMICON Southeast Asia 2025

CUF|ShieldPlus™ will be unveiled at SEMICON Southeast Asia, May 20–22, 2025, in Singapore, where Nanostone will present performance benchmarks, case studies, and system design strategies tailored to fabs planning or expanding water reuse initiatives.

Learn More

To learn more about CUF|ShieldPlus™ or speak with a Nanostone expert ahead of SEMICON Southeast Asia 2025, visit https://nanostone.com/technology-cufshieldplus-ceramic-membrane or contact info@nanostone.com.

About Nanostone Water

Nanostone is a leading provider of advanced ceramic-based filtration solutions designed to remove suspended solids and pathogens from even the most challenging waters. The company’s reliable, robust, and cost-effective processes significantly reduce land and environmental footprints. Operating an automated state-of-the-art module manufacturing plant in Germany, Nanostone serves global desalination, municipal water treatment, and industrial water treatment markets through commercial offices in Asia, the Middle East, Europe, and the U.S.

For more information, please contact:

Rob Boogaard

Email: rob.boogaard@nanostone.com

Nanostone Water, Inc.

One Marine Park Drive, Suite 1410

Boston, MA 02210, USA

Email: info@nanostone.com

Website: www.nanostone.com