Sea Water Desalination – Nanostone Ceramic Membrane

Applications

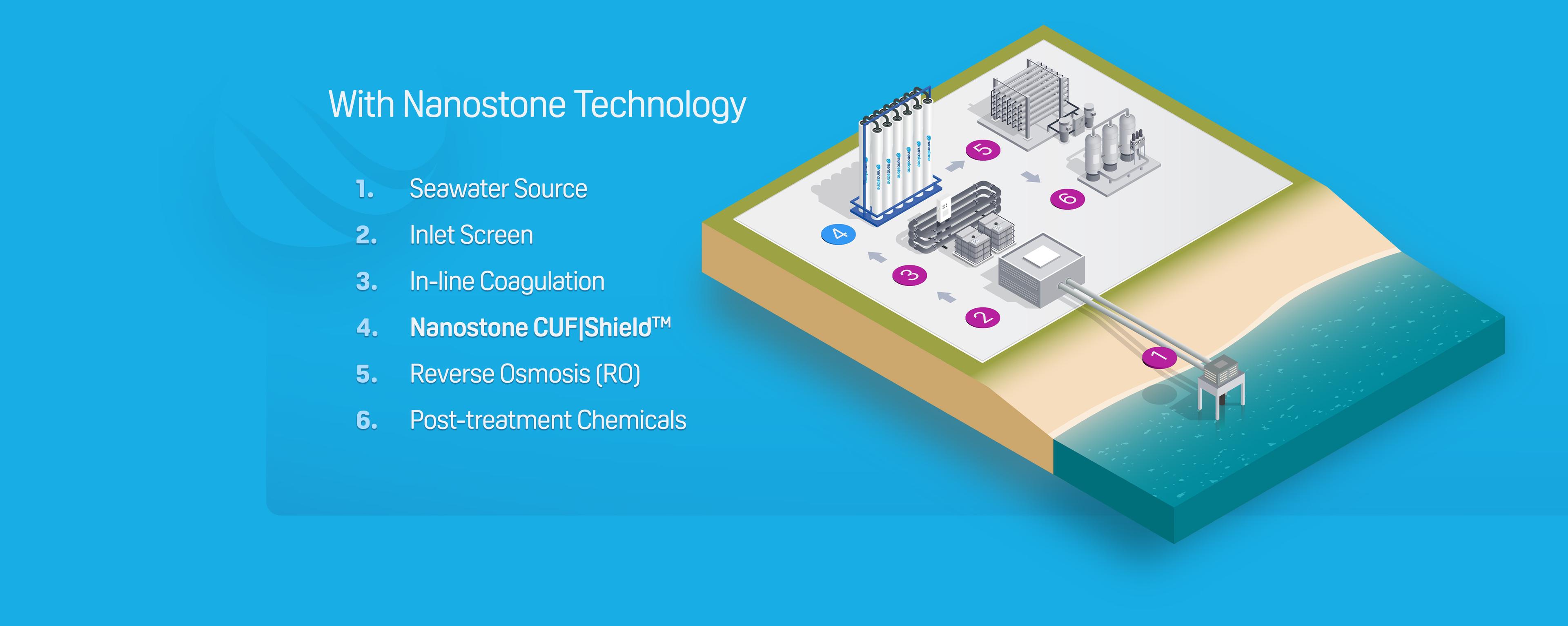

Sea Water Desalination

Advanced Ceramic Membrane Filtration for Sea Water Desalination Treatment

Why Nanostone for Sea Water Desalination?

Approach & Benefits

Our Ceramic Ultrafiltration (CUF) Membranes offer an innovative solution to the challenges of sea water desalination.

Compact Footprint:

Our system significantly reduces the required footprint, as much of the pretreatment is not necessary. This is particularly beneficial in densely populated or environmentally sensitive areas.

Effective Contaminant Removal:

Our membranes provide a robust barrier against suspended particles, significantly reducing the fouling rate of downstream Reverse Osmosis (RO) membranes and increasing their operational lifespan.

Continued Operations During Algal Bloom Events:

Our membranes are designed to maintain stable operations even during harmful algal bloom (HAB) events, preventing shutdowns and service disruptions.

High Recovery Rate:

Reduced Operational Costs:

Proven Success

Nanostone's Impact in Sea Water Desalination

Tuas Desalination Plant Case Study

- Challenge Overview: The Tuas facility in Singapore experienced issues with capacity due to unreliable pretreatment when using polymeric membranes. High levels of dissolved organics and suspended solids led to frequent fouling and operational disruptions.

- Nanostone Solution: Nanostone installed a full-scale commercial demonstration module of its ceramic desalination pretreatment system. This system effectively handled the challenging sea water, ensuring stable operation even during harmful algal blooms.

- Benefits Achieved:

- Achieved 97% plant availability.

- Reached a 97% recovery rate.

- Demonstrated tolerance to variable water quality without performance issues.

- Reduced operational costs by eliminating multiple pretreatment steps and decreasing chemical usage.

For more details, visit Tuas Desalination Plant project page:

Barka Desalination Plant Case Study

- Challenge Overview: The Barka facility in Oman struggled with frequent algal blooms, leading to shutdowns and reduced capacity.

- Nanostone Solution: Implementing Nanostone’s ceramic ultrafiltration membranes provided a robust pretreatment that effectively managed the variable water quality and minimized fouling.

- Benefits Achieved:

- Consistent SDI below 1.5 and turbidity below 0.2 NTU.

- Increased reliability and operational efficiency.

- Improved water quality feeding into the RO system, reducing overall operational costs.

Common Questions

About our Sea Water Desalination Application

How does Nanostone support seawater desalination?

How does Nanostone support seawater desalination?

Nanostone’s ceramic membranes play a crucial role in seawater desalination by providing robust pre-treatment that protects Reverse Osmosis (RO) membranes. This stage improves feed water quality by filtering out particles, debris, microorganisms, suspended solids, and silt, ensuring that RO membranes operate efficiently and with a prolonged lifespan. Effective pre-treatment reduces the risk of fouling from bacteria or algae, which optimizes operational costs and supports safe, economical plant operations.

Can Nanostone’s membranes handle harsh seawater conditions?

Can Nanostone’s membranes handle harsh seawater conditions?

Yes, Nanostone’s ceramic membranes are specifically designed to handle the demanding conditions of seawater environments. These challenges include high salinity, elevated turbidity, silt, and biological contaminants like bacteria and algae, which often cause fouling and disrupt conventional systems. Nanostone’s durable membranes offer excellent chemical resistance and fouling prevention, ensuring stable, efficient filtration in seawater pre-treatment.

What specific advantages do ceramic membranes have over traditional polymeric membranes in seawater desalination?

What specific advantages do ceramic membranes have over traditional polymeric membranes in seawater desalination?

Ceramic membranes offer significant advantages over traditional polymeric membranes in seawater desalination, particularly in handling harsh conditions. They provide superior chemical resistance and higher thermal stability, which allows for more rigorous cleaning processes, ensuring a longer lifespan. Additionally, ceramic membranes excel during seasonal algae blooms, or “algal peaks”, by maintaining stable filtration performance when polymeric membranes might struggle with fouling.

Sweetspot Applications

Explore Nanostone's Advanced Water Treatment Applications

Innovative Ceramic Membrane Solutions for Cleaner, More Sustainable Water

Nanostone's ceramic membranes enhance RO system performance by optimizing the pretreatment process. They efficiently remove suspended solids and pollutants, ensuring better water quality and reducing fouling risks. Ideal for both municipal and industrial applications, these membranes improve efficiency, sustainability, and cost-effectiveness in water treatment.