Ceramic Membrane Technology - Nanostone Water Solutions

Our Technology Solutions

Leading the Future of Water Filtration and Treatment

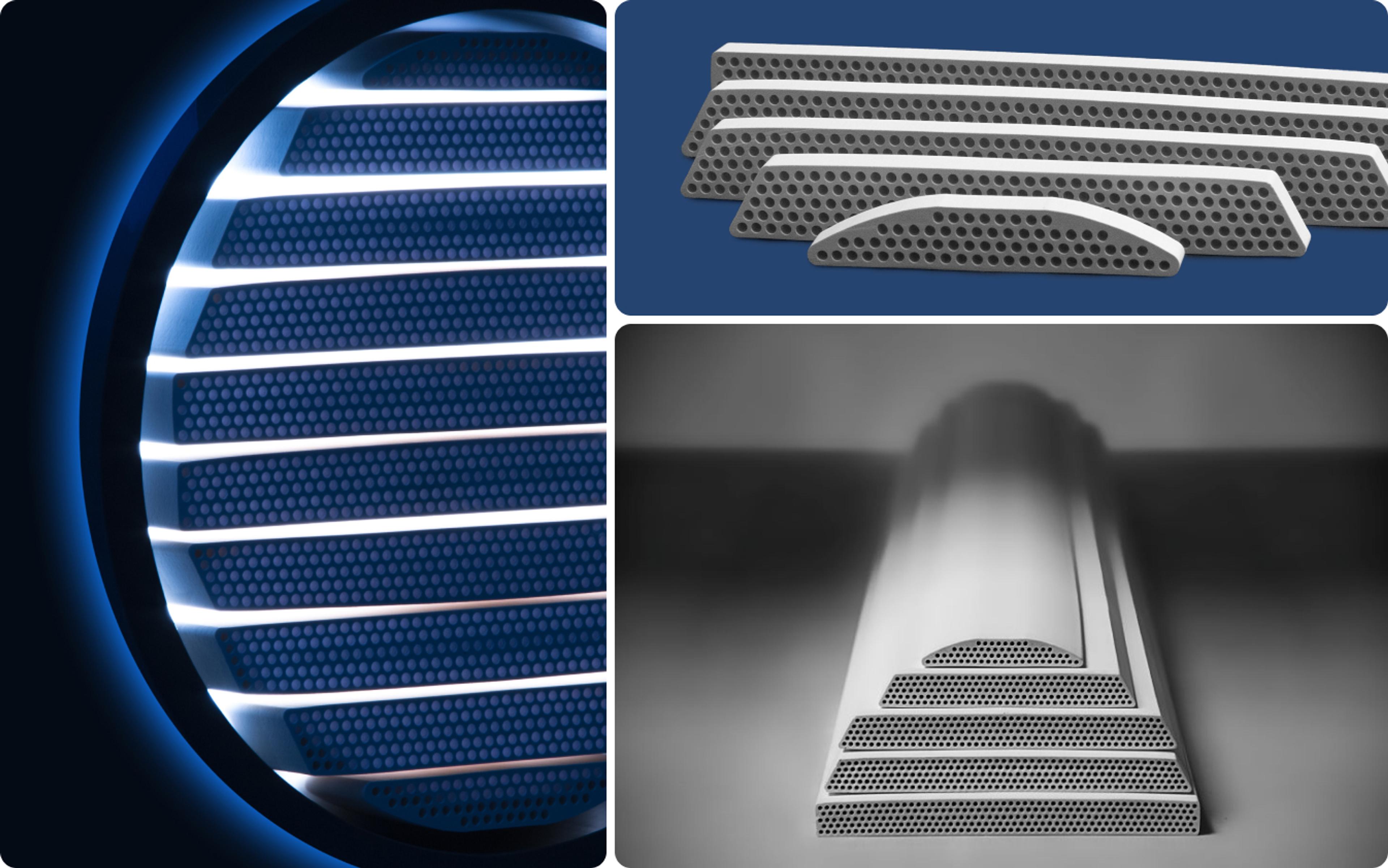

Next Generation Membrane

Ceramic Membrane

Patented Design

Segmented Monolith Design

High Flowrate Module

High Flowrate Module

Solutions Optimized for the Markets We Serve

At Nanostone, we tailor our solutions to meet the unique demands of each market we serve.

Our offerings encompass module specifications, system designs, operating protocols, monitoring and control systems, and warranties, all optimized to address the specific challenges our customers face. These are the markets we focus:

Municipal Water Treatment

We understand that municipal water management is essential for safeguarding public health, ensuring resource accountability, and protecting the environment amid growing challenges.

Industrial Water Treatment

In the industrial sector, efficient water management is crucial for sustainability and compliance, as water is a vital resource in various processes across all industries.

Common Questions

About our Ceramic Membrane Technology

What are ceramic membranes?

What are ceramic membranes?

They are advanced filtration components made of inorganic materials and feature several distinct layers: a microporous active layer for fine filtration, an intermediate layer for structural support, and a macroporous outer layer that adds mechanical strength. These membranes are exceptionally resistant to chemical and thermal stress, making them well-suited for challenging environments.

How does Nanostone's technology improve water treatment?

How does Nanostone's technology improve water treatment?

Our advanced ceramic membranes enhance efficiency, reduce maintenance costs and the overall footprint of the treatment plant. Compared to traditional water filtrations systems, the ceramic membrane has a more extended lifespan.

How does Nanostone address limited space in installations?

How does Nanostone address limited space in installations?

Nanostone addresses space limitations in water treatment by using ceramic ultrafiltration membranes that reduce the need for large, traditional pre-treatment setups. This compact design allows facilities to operate effectively within constrained areas, such as in the Martindale project, where space was limited due to surrounding neighborhoods.

What types of projects does Nanostone undertake?

What types of projects does Nanostone undertake?

Nanostone handles water treatment projects in municipal, industrial, and wastewater sectors, offering efficient, space-saving solutions. It treats surface water, groundwater, seawater, and reuse applications in the pre-treatment process. This flexibility ensures compliance and meets specific water source needs with customized ceramic membrane technology.

How does Nanostone customize its systems?

How does Nanostone customize its systems?

Nanostone tailors its water treatment systems by evaluating factors such as water quality, treatment objectives, operational conditions, and space limitations. Adjustments are made based on flux requirements, fouling potential, permeate quality, and the water source. This customized approach guarantees optimal performance, compliance with regulations, and effective solutions for each unique project.

What are the benefits of using Nanostone's systems?

What are the benefits of using Nanostone's systems?

Nanostone’s systems provide high efficiency, durability, and low maintenance costs, designed for challenging water sources and limited spaces. Using advanced German technology, these ceramic membranes effectively treat complex contaminants in a compact footprint, ensuring long-term, cost-effective performance.