Mining Wastewater Treatment - Nanostone Ceramic Membranes

Applications

Mining Wastewater

Advanced Ceramic Membrane Filtration for Mining Wastewater Treatment

Why Nanostone for Mining Wastewater?

Approach & Benefits

Our Ceramic Ultrafiltration (CUF) Membranes provide an effective solution for mining wastewater treatment, addressing both quality and operational challenges.

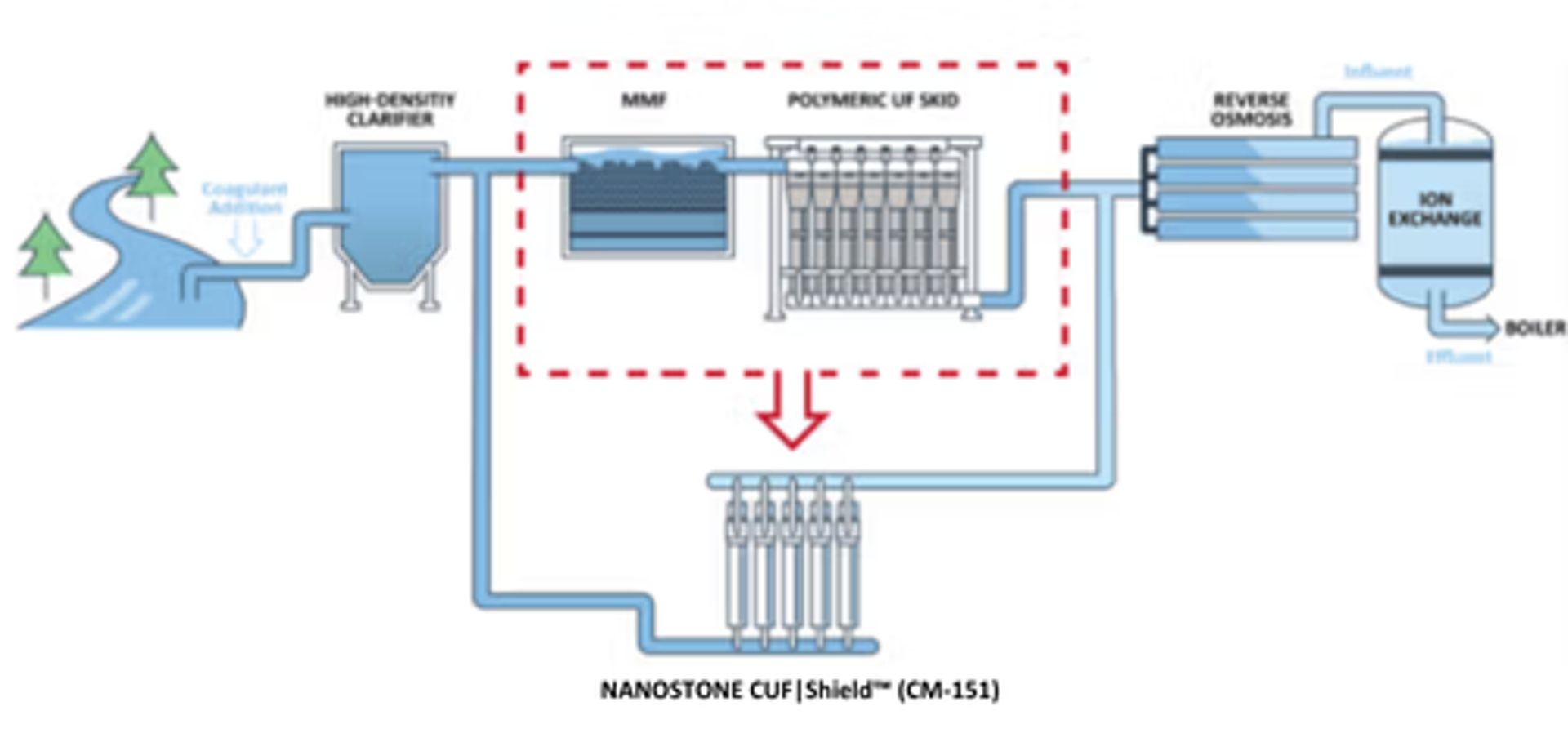

- Simplified Treatment Scheme: Conventional approaches typically use multimedia filtration and polymeric UF membranes; Nanostone replaces both in a single-unit operation, simplifying the treatment process.

- Long-Lifetime Physical Barrier: Nanostone removes abrasive coal particles that lead to shortened PUF lifetimes and disrupt downstream RO operations.

- Robust Operation: With regulations driving the need for RO, Nanostone’s solution is ideal for regions with stringent reuse and Zero-Liquid Discharge (ZLD) standards.

Proven Success

Nanostone's Impact in Mining Wastewater

Xiaojihan Coal Mine Case Study

- Challenge Overview: The Xiaojihan Coal Mine faced issues with its existing PUF membrane system, including frequent fouling and high maintenance, which compromised treatment capacity.

- Nanostone Solution: Implementing the CUF|Shield™ (CM-151) ceramic ultrafiltration membrane system provided a robust, reliable solution that stabilized the downstream RO system and increased treatment capacity by 44%.

- Benefits Achieved:

- Reduced maintenance needs due to fewer chemical cleanings.

- Improved system reliability and compliance with environmental regulations.

- Increased operational efficiency and extended membrane life.

For more details, visit Xiaojihan Coal Mine Company project page

Lithium Extraction in China’s Salt Lakes Case Study

- Challenge Overview: The project required robust treatment of high TDS and TSS wastewater to support lithium extraction processes.

- Nanostone Solution: The CUF|Shield™ (CM-151) ceramic ultrafiltration membrane system was implemented to manage the harsh conditions and ensure high-quality feed water for downstream processes.

- Benefits Achieved:

- Increased reliability and reduced maintenance requirements.

- Enhanced water quality, supporting efficient lithium extraction.

- Achieved compliance with stringent environmental regulations.

For more details, visit Lithium Extraction in China’s Salt Lakes Company project page

Common Questions

About our Mining Wastewater Application

How does Nanostone’s technology treat mining wastewater?

How does Nanostone’s technology treat mining wastewater?

Nanostone’s technology treats mining wastewater by using Ceramic Ultrafiltration Membranes, which simplify the process by combining the functions of both multimedia filtration and polymeric UF in a single unit. This reduces operational complexity and improves efficiency. The membranes effectively remove abrasive coal particles, protecting downstream Reverse Osmosis (RO) systems and extending their lifespan. Nanostone’s solution is particularly suited for regions with strict reuse and Zero-Liquid Discharge (ZLD) regulations, ensuring compliance with environmental standards while maintaining robust and reliable operation.

How do you adapt your solutions to fluctuations in the quality of wastewater we experience in mining?

How do you adapt your solutions to fluctuations in the quality of wastewater we experience in mining?

Nanostone’s technology adapts to fluctuations in mining wastewater quality by offering robust filtration capabilities that can handle variable contaminant loads. The Ceramic Ultrafiltration Membranes are designed to efficiently remove suspended solids, including abrasive particles, and protect downstream processes like Reverse Osmosis (RO). Their durability ensures consistent performance, even with changes in water composition, and minimizes the need for frequent maintenance. The flexibility of Nanostone’s solution makes it suitable for environments with fluctuating water quality, ensuring reliable operation under diverse conditions.

Sweetspot Applications

Explore Nanostone's Advanced Water Treatment Applications

Innovative Ceramic Membrane Solutions for Cleaner, More Sustainable Water

Nanostone's ceramic membranes enhance RO system performance by optimizing the pretreatment process. They efficiently remove suspended solids and pollutants, ensuring better water quality and reducing fouling risks. Ideal for both municipal and industrial applications, these membranes improve efficiency, sustainability, and cost-effectiveness in water treatment.