Boiler Feed Water for Power Generation – Nanostone Ceramic Membrane

Applications

Boiler Feed Water

Innovative Ceramic Membrane Filtration for Industrial Boiler Feed Water

Why Nanostone for Boiler Feed Water for Power Generation?

Approach & Benefits

Our Ceramic Ultrafiltration (CUF) Membranes provide an innovative solution to challenges such as source water variability, high turbidity, constrained footprints, among others, in treating boiler feed water, offering several key benefits:

- Compact Footprint: Our solution can fit into the small spaces that are typically available for water treatment equipment in these facilities. This is essential for retrofits and expansions where space is limited.

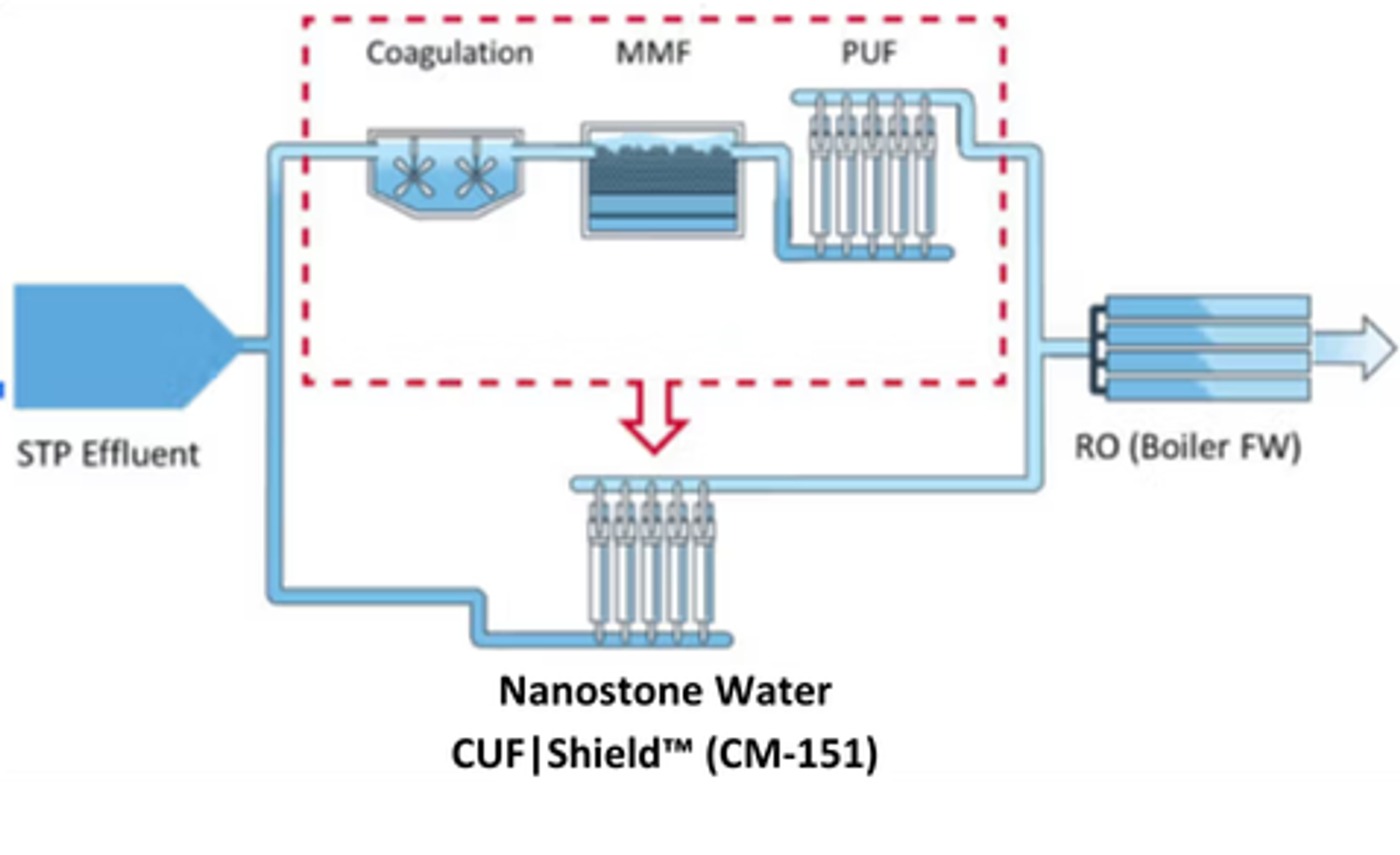

- Simplified Treatment Scheme: Competing approaches typically use multimedia filtration and polymeric UF membranes. We replace both in a single-unit operation, simplifying the treatment process and reducing the overall footprint and complexity of the system.

- Robust Operation: Our solution is robust against the variability inherent in surface waters often used to supply boiler feed, ensuring consistent performance and quality despite changes in feed water.

- Increased Recovery: Our system achieves higher recovery than competing schemes, resulting in increased uptime and lower overall operational expenses (OPEX). This is achieved through efficient contaminant removal and reduced fouling of downstream RO systems.

- Extended Membrane Life: Our ceramic membranes deliver a longer lifespan, reducing replacement frequency and associated costs.

Proven Success

Nanostone's Impact in Boiler Feed Water

Zhejiang Hengyang Thermal Power Company Case Study

- Benefits Achieved:

- Consistent delivery of high-quality water to the RO system with SDI values < 2 and turbidity readings < 0.1 NTU.

- Significant reduction in operating costs due to lower chemical usage and increased membrane lifespan.

- Improved system reliability and reduced maintenance frequency.

For more details, visit Zhejiang Hengyang Thermal Power Company

project page.

Hengyang Thermal Power Company Case Study

- Benefits Achieved:

- Enhanced treatment reliability and consistency.

- Reduced chemical usage and operational costs.

- Achieved regulatory compliance with higher system recovery rates.

For more details, visit Hengyang Thermal Power Company

project page

Common Questions

About our Boiler Feed Water Application

How does Nanostone’s technology improve boiler feed water treatment?

How does Nanostone’s technology improve boiler feed water treatment?

Nanostone’s ceramic membrane technology significantly improves boiler feed water treatment by offering superior filtration performance, even in challenging water conditions. Their membranes effectively remove suspended solids, organic matter, and other impurities that could cause scaling and corrosion in boilers. Unlike traditional polymeric membranes, Nanostone's ceramic membranes are more resistant to fouling and can operate in harsher feedwater conditions without frequent cleaning, reducing maintenance costs and downtime.

How do your membranes help reduce scaling and corrosion in my boilers?

How do your membranes help reduce scaling and corrosion in my boilers?

Nanostone’s ceramic membranes effectively combat corrosion by delivering high-purity feedwater with minimal suspended solids, dissolved gases, and other corrosive contaminants. Their advanced filtration technology ensures that particulates, which could indirectly promote corrosion by interfering with de-aeration or chemical treatment processes, are thoroughly removed. Furthermore, the membranes' superior performance enhances the effectiveness of downstream treatments, such as de-aeration and chemical dosing, providing additional protection against corrosion.

Sweetspot Applications

Explore Nanostone's Advanced Water Treatment Applications

Innovative Ceramic Membrane Solutions for Cleaner, More Sustainable Water

Nanostone's ceramic membranes enhance RO system performance by optimizing the pretreatment process. They efficiently remove suspended solids and pollutants, ensuring better water quality and reducing fouling risks. Ideal for both municipal and industrial applications, these membranes improve efficiency, sustainability, and cost-effectiveness in water treatment.