Municipal Wastewater Reuse - Nanostone Ceramic Membranes

Applications

Municipal Wastewater Reuse

Advanced Ceramic Membrane Filtration for Municipal Wastewater Reuse Treatment

These include agricultural irrigation, green space maintenance (such as golf courses), and as feed for industrial processes. These waters contain high levels of organics and microorganisms, which must be removed for reuse. Further treatment, such as reverse osmosis (RO), may also be required for specific applications like boiler feed water in power plants. Proper pre-treatment is essential to ensure overall system reliability and to minimize operating costs

Why Nanostone for Municipal Wastewater Reuse?

Approach & Benefits

Our Ceramic Ultrafiltration (CUF) Membranes provide an effective solution for wastewater treatment, addressing both quality and operational challenges:

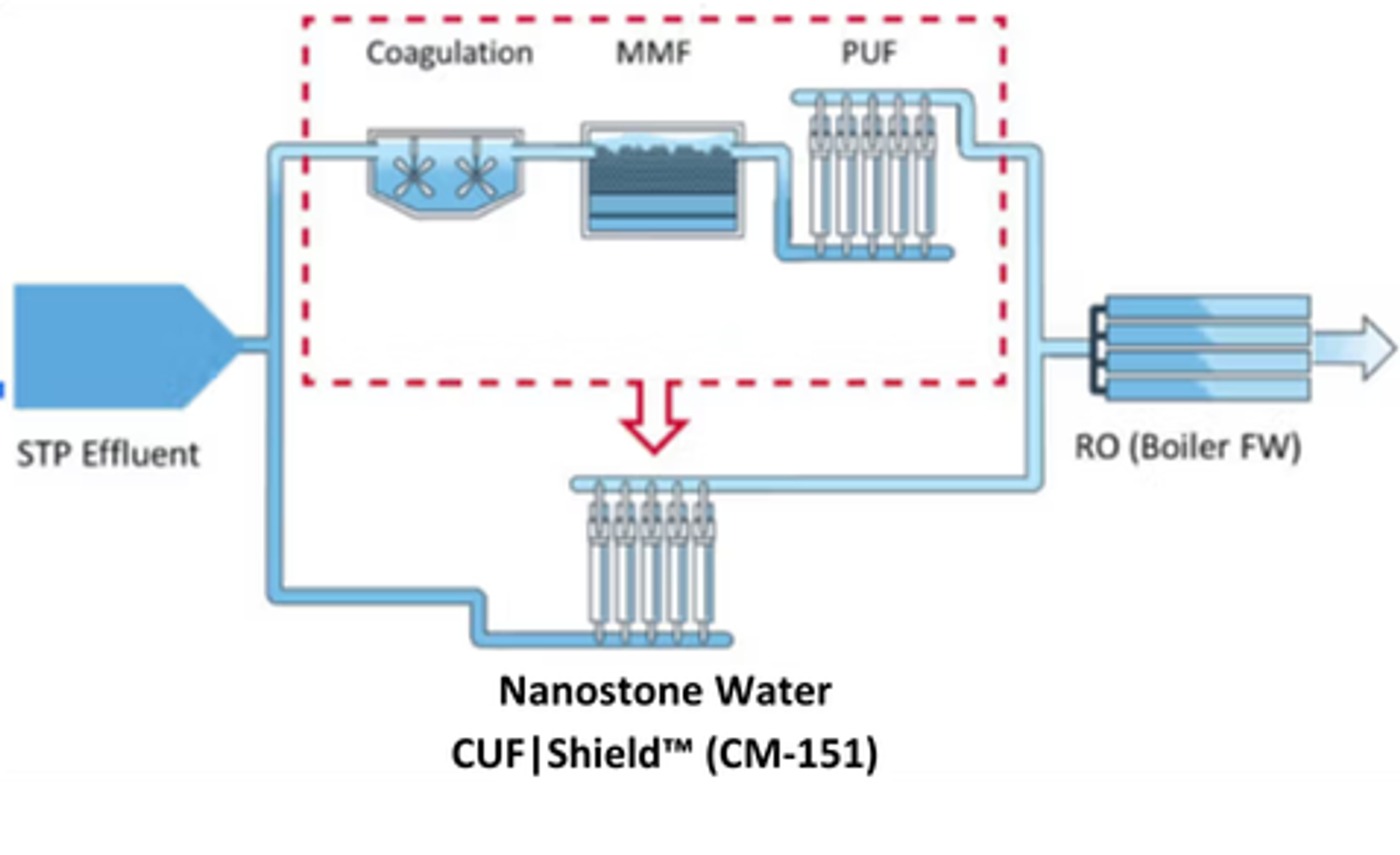

- Simplified Treatment Scheme: Competing approaches typically use multimedia filtration and polymeric UF (PUF) membranes. Nanostone replaces both in a single-unit operation, simplifying the treatment process.

- Robust: Nanostone’s solution is robust against the variability common in municipal wastewater effluent sources.

- Long-Lifetime Physical Barrier: Nanostone membranes remove microorganisms and coagulated organics that foul PUF and downstream RO membranes.

- Increased Capacity and Efficiency: The CUF|Shield™ (CM-151) ceramic UF system increases overall treatment capacity, optimizes process operations by eliminating pre-filtration steps, and provides stable, long-term performance.

Proven Success

Nanostone's Impact in Municipal Wastewater Reuse

Municipal Wastewater Reuse at Baotou Power Plant Case Study

- Challenge Overview: The Baotou power plant faced the challenge of increasing water scarcity, prompting the need to evaluate the use of impaired water sources. The pre-treatment of effluent from a local sewage treatment plant was complex and expensive to operate, requiring an efficient and cost-effective solution.

- Nanostone Solution: The power plant implemented the Nanostone CUF|Shield™ (CM-151) ceramic ultrafiltration membrane system. This system provided a trouble-free option, reducing the complexity of pre-treatment steps, improving efficiency, and increasing flux 3-5 times compared to conventional polymeric UF membranes. The CUF|Shield™ (CM-151) system also lowered overall maintenance requirements while ensuring reliable performance for a lifetime 2-6 times longer than polymeric UF systems.

- Benefits Achieved:

- Increased design flux by 3-5 times compared to conventional polymeric UF membranes.

- Extended membrane lifespan by 2-6 times, reducing the need for frequent replacements.

- Significant cost savings, projected to save over $700,000 USD annually in water savings.

- Reliable operation with minimal cleaning and oversight, ensuring consistent performance.

Common Questions

About our Municipal Wastewater Reuse Application

How does Nanostone’s technology support municipal wastewater reuse?

How does Nanostone’s technology support municipal wastewater reuse?

Nanostone ceramic membranes, particularly in the context of municipal wastewater reuse, excel in delivering high-efficiency filtration that supports the treatment of effluent for safe non-potable applications. These membranes stand out for their ability to handle challenging water conditions with minimal need for extensive pre-treatment. They effectively remove suspended solids, organic matter, and microorganisms, producing high-quality permeate suitable for reuse in various settings such as irrigation, industrial processes, or cooling systems.

Can Nanostone’s systems handle high contaminant loads?

Can Nanostone’s systems handle high contaminant loads?

Nanostone’s ceramic membrane systems are highly effective in handling water with high contaminant loads, thanks to their robustness and resistance to fouling. They can treat challenging feedwater with high levels of suspended solids, organic matter, and microorganisms, reducing the need for extensive pre-treatment. This simplifies operations, maintains high recovery rates, and ensures consistent water quality, making them ideal for applications like municipal wastewater reuse and industrial water recycling.

Are Nanostone membranes adaptable to existing systems, or will I need significant infrastructure changes?

Are Nanostone membranes adaptable to existing systems, or will I need significant infrastructure changes?

Nanostone ceramic membranes are highly adaptable to existing water treatment systems, often allowing seamless retrofitting without requiring significant infrastructure changes. Their design minimizes the need for extensive modifications, simplifying integration into current setups. This flexibility enables facilities to enhance their water treatment performance efficiently, reducing installation time and costs.

Sweetspot Applications

Explore Nanostone's Advanced Water Treatment Applications

Innovative Ceramic Membrane Solutions for Cleaner, More Sustainable Water

Nanostone's ceramic membranes enhance RO system performance by optimizing the pretreatment process. They efficiently remove suspended solids and pollutants, ensuring better water quality and reducing fouling risks. Ideal for both municipal and industrial applications, these membranes improve efficiency, sustainability, and cost-effectiveness in water treatment.