CUF|ShieldPlus™ (CM-151 ME)Ceramic Membranes | Solving Your Fab’s Toughest Wastewater Challenges

CUF|ShieldPlus™ (CM-151 ME) — Solving Your Fab’s Toughest Wastewater Challenges

Chips Are Getting Smaller. The Fab’s Water Problem Is Getting Bigger.

Semiconductor fabs are generating highly complex wastewater of exceptional chemical aggressiveness, particulate load, and regulatory sensitivity. Traditional treatment systems are being pushed to their limits. That’s where CUF|ShieldPlus™ comes in.

Built for Your Most Demanding Process-Critical Streams

CUF|ShieldPlus™ is Nanostone’s precision-engineered ceramic ultrafiltration (CUF) module, developed to tackle the hardest wastewater challenges in advanced semiconductor manufacturing:

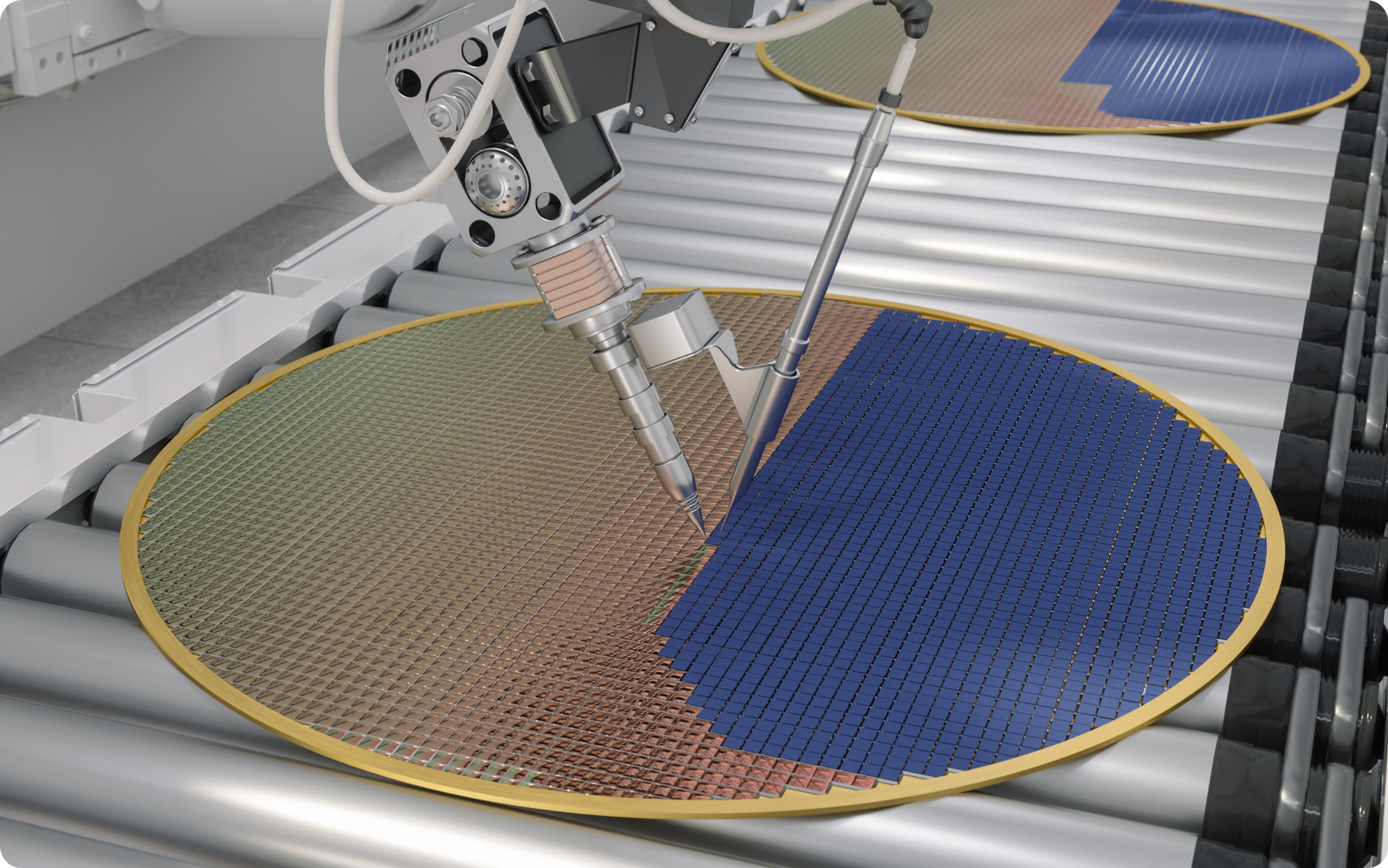

- Grinding, Cutting & Dicing: Handles abrasive, silicon-rich slurries without flocculation or bulky clarifiers.

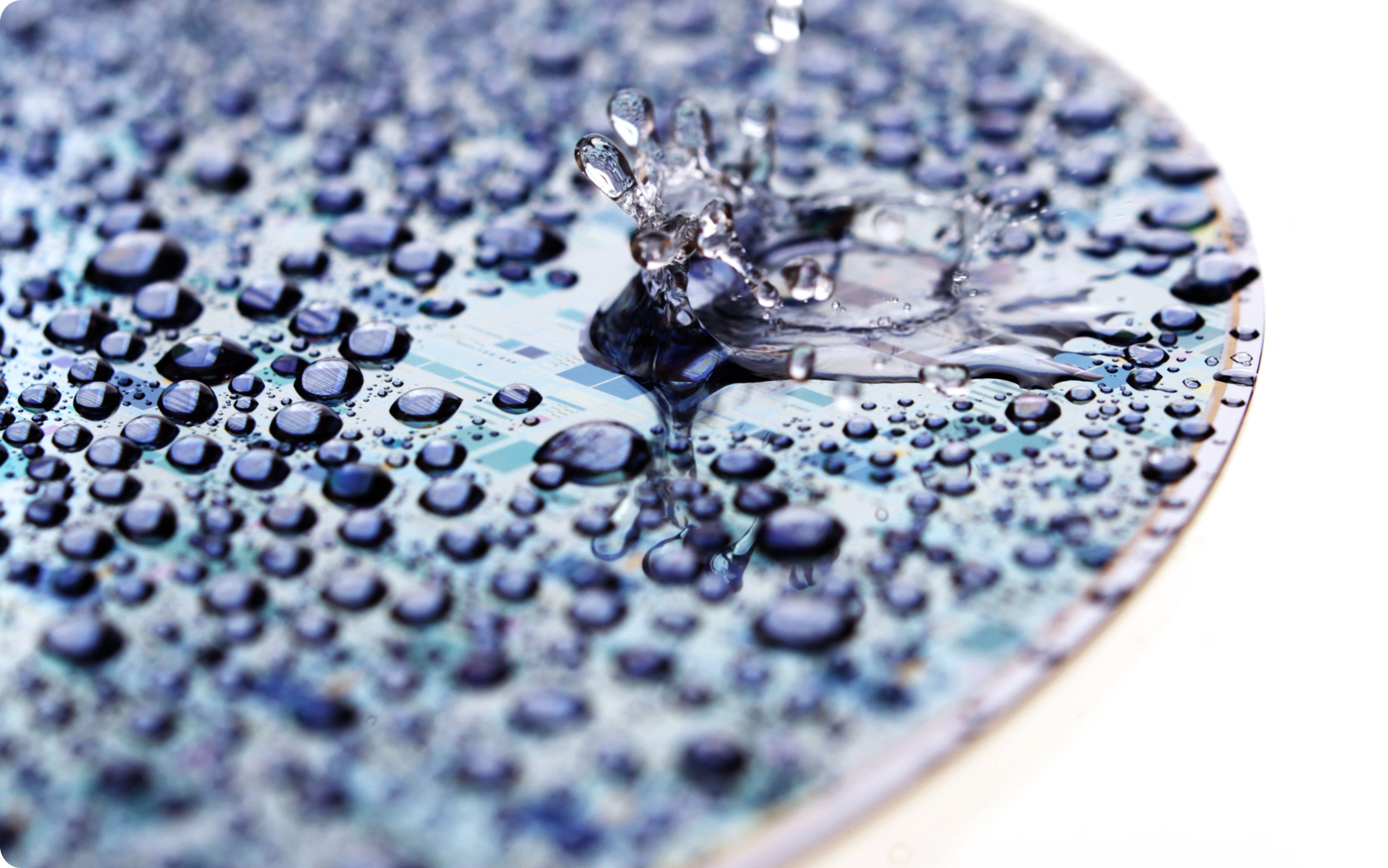

- Chemical Mechanical Planarization (CMP): Captures nano-abrasives, metals and surfactants at high flux and low fouling.

- Hydrofluoric Acid & Heavy Metals: After pH-adjustment, tackles fluoride complexes and metal-laden wastewater with corrosion-resistant ceramics.

- Other Aggressive Streams: Treats ammonia, organics and composite wastewaters that overwhelm conventional UF.

These process streams account for over 50 % of total fab wastewater—and they carry the highest risk for yield loss, permit violations and costly downtime.

Why CUF|ShieldPlus™ is the premier choice?

- Superior Fouling Resistance: Maintains performance in high–surfactant and high–particulate environments without frequent cleaning.

- Exceptional Chemical & Thermal Stability: Withstands aggressive pH, solvents, and temperature fluctuations common in semiconductor processes.

- Streamlined Pretreatment: Eliminates the need for DAF, flocculation, or large clarifiers, simplifying system design and footprint.

- Seamless Integration: Delivers low-SDI permeate for direct coupling with RO and ion-exchange stages, enabling turnkey water-reuse loops.

Built to make a real difference

Tangible Benefits & Performance

Up to 95 % Water Recovery: Recover nearly all process water with no pretreatment trains, maximizing reuse and supporting zero liquid discharge (ZLD), water circularity, and ESG compliance.

Long Membrane Life & Low Cleaning Frequency: Ceramic membranes resist surfactants, abrasives and extreme pH swings for 3–5 years of continuous operation.

Compact, Retrofit-Ready Footprint: Modular skids fit within existing fab layouts, freeing up valuable floor space.

Application Deep Dives: Where CUF|ShieldPlus™ Excels

Grinding, Cutting & Dicing, CMP and HF wastewater aren’t just difficult; they’re expensive, inconsistent, and increasingly regulated. These are the streams, among others, that clog systems, foul membranes, and force operators into constant workarounds. Each one demands a level of filtration performance that conventional systems can’t reliably deliver.

CUF|ShieldPlus™ is engineered specifically for these conditions. This ceramic membrane module performs where other membranes degrade, clog, or fail.

Download the ‘Solving the Toughest Wastewater Challenges in the Fab’ document to discover how this solution handles the fabs most challenging wastewater streams, both Process-Critical and Utility wastewater Streams.

Field-Proven in 40+ Fabs Worldwide

Deployed in adavanced fabs from North America to Asia, CUF|ShieldPlus™ consistently delivers:

- Seamless Polymeric Replacement: Retires fouled polymeric membranes with minimal disruption.

- Lower OPEX & Extended Uptime: Cuts operating costs and pushes cleaning cycles far beyond conventional intervals.

- Exceptional Water Recovery: Recovers up to 95% of process water for reuse or ZLD integration

- Compact Footprint: Reduces system footprint by over 40%, freeing valuable space.

Ready to Transform Your Wastewater into a Strategic Asset?

Whether you’re grinding, cutting & dicing, expanding CMP capacity, mitigating HF discharge, or deploying a ZLD strategy, CUF|ShieldPlus™ empowers your fab to:

- Protect yield: Maintain uninterrupted production by preventing fouling-related downtime.

- Reduce chemical use and labor: Streamline operations with reduced cleaning cycles and lower reagent consumption.

- Leverage Water as an Asset: Turn high-risk effluents into a reliable resource and strengthen your sustainability profile.

For other semiconductor wastewater applications, CUF|Shield™ is available for utility and facility wastewater streams such as cooling towers, boilers, and HVAC condensate recovery.