Nanostone Water - Advanced Ceramic Membrane Water Solutions

Welcome to Nanostone

Leading the Way in Ceramic Ultrafiltration (CUF) Membrane Technology for Sustainable Water Filtration Solutions

Welcome to Nanostone where the future of water safety and sustainability is now. We are at the forefront of tackling the impending global water crisis—an urgency once seen as a distant challenge, now unfolding before our eyes.

Water, the lifeblood of our cities and industries, faces increasing threats from pollution and scarcity. The rapid pace of urbanization and industrial growth has intensified the demands on our water reserves, with rivers, lakes, and aquifers suffering from significant pollution and depletion.

Climate change intensifies these challenges, causing more frequent and severe storms that lead to runoff contamination. Warmer temperatures promote the growth of harmful algal blooms and microorganisms, posing serious challenges to our existing water treatment plants.

In response to these growing pressures, additional space-intensive water treatment steps are required. Yet, in dense urban and industrial settings, the available physical space is limited. Existing treatment facilities are stretched to their limits, choked by the very progress they were designed to support.

Global Leaders in Ceramic Ultrafiltration Technology and Water Solutions

Nanostone Water, co-headquartered in the USA and Germany, is a global leader in water technology solutions specializing in ceramic ultrafiltration (CUF).

Our cutting-edge technology is engineered and produced in Germany, ensuring the highest standards of quality and innovation. With complete in-house control over ceramic production, robust R&D, and in-depth application process expertise, our capabilities include project management, engineering design, and service engineering—all supported by lifetime engineer-backed warranties.

Our exceptionally durable ceramic filtration membranes, developed using top-tier engineering methodologies and verified through extensive pilot studies in various applications, are produced in our ISO 9001-certified automated factory, assuring consistent quality across all projects.

With hundreds of successful projects worldwide, serving leading water utilities and industry giants, Nanostone delivers advanced, customized water treatment solutions that are reliable, robust and proven to withstand the test of time, fulfilling the diverse needs of our municipal and industrial clients with flawless results.

——————

——————

Discover how Nanostone’s compact and robust process tackles your challenging water while eliminating the need for additional, cost and space-intensive treatment steps.

Our Impact in Numbers

Where the future of water safety and sustainability is now. We are at the forefront of tackling the impending global water crisis—an urgency once seen as a distant challenge, now unfolding before our eyes.

12+ years of industry experience

Established leadership and proven expertise since 2012

Presence across 3 continents: Americas, Europe, and Asia

Supporting clients worldwide with proven solutions

100% German manufacturing under ISO 9001, ISO14001 & ISO 45001

Precision and quality guaranteed in every product

95% wastewater reduction

Commitment to sustainability through innovative processes

95% water recovery in industrial applications

Advanced resource optimization for critical systems

Turbidity below 0.05 NTU in 95% and under 0.15 NTU in 100% of cases

Effectively tackling harmful algal blooms and other contaminants

Why Nanostone

Our ceramic filtration membranes aren’t just literally rock-solid; they’re making us the global rockstars of water filtration

Ceramic Technology Experts

Ceramic Technology Experts

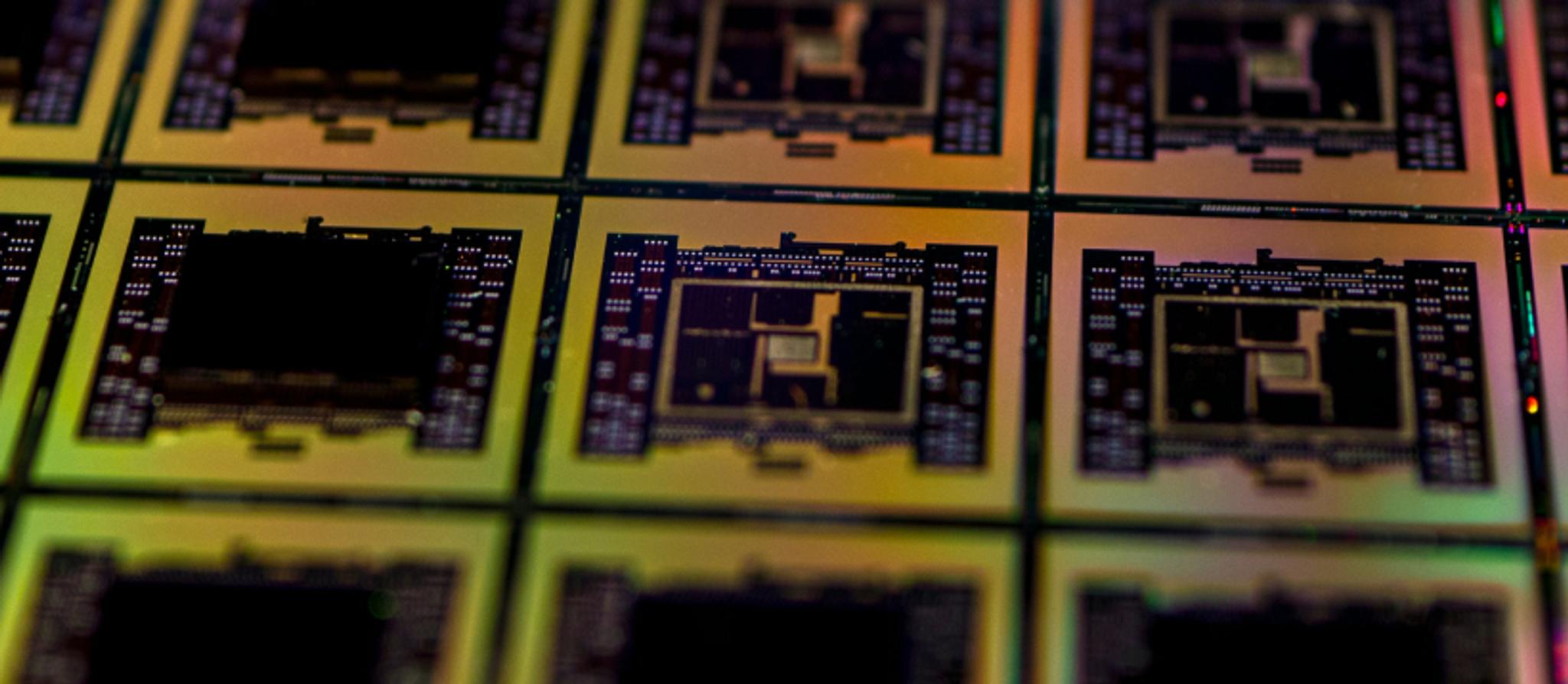

Nanostone leads the field in ceramic technology for water treatment, backed by a team of the world’s leading experts in ceramic filtration. Our extensive experience is reflected in our innovative ceramic membranes, renowned for their unmatched durability and efficiency. Crafted with proprietary nanomaterials, these membranes feature a precise 30 nm pore size, ensuring superior removal of contaminants and high flux performance. This expertise makes Nanostone a trusted authority in delivering advanced, reliable filtration solutions.

Application Process Experts

Application Process Experts

Nanostone has a thorough grasp of the unique requirements of a broad range of applications in the municipal and industrial sectors, enabling us to deliver precisely tailored and innovative solutions. Our approach blends advanced technology with practical expertise, ensuring optimal performance in purifying municipal water or managing industrial effluents. This broad expertise not only underscores our ability to address diverse challenges but also reinforces Nanostone’s role as a reliable partner in water treatment across various applications.

Systems and Solutions Experts

Systems and Solutions Experts

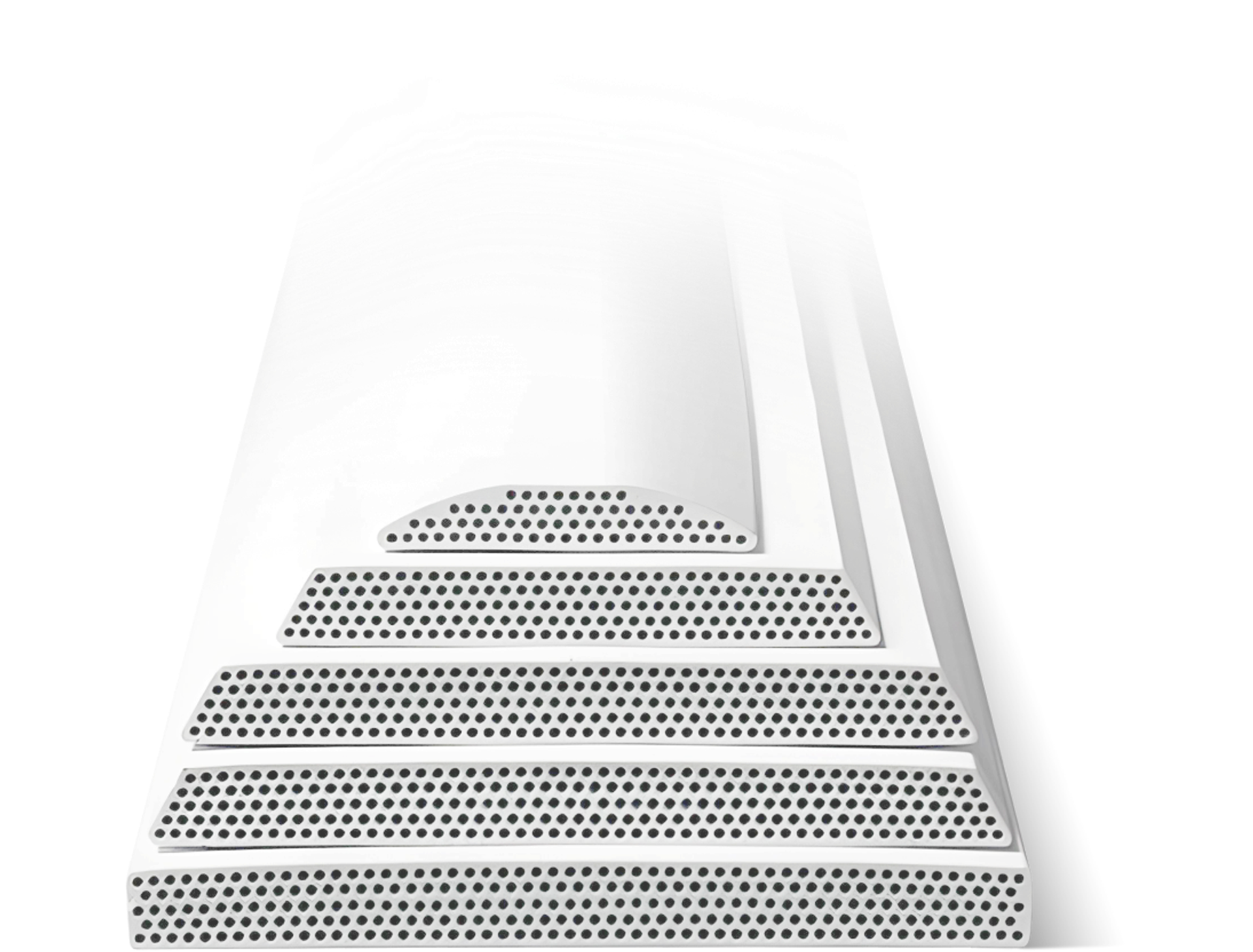

Nanostone and its partners excel in delivering modular yet tailored systems and solutions that specifically address the unique needs of different market sectors. We meticulously optimize system designs and operating protocols to ensure our offerings efficiently handle each customer’s specific challenges. Our systems are designed for high flow rates, minimizing space requirements, and are backed by warranties that guarantee reliable performance under high solids loading. This commitment to modular customization and robust efficiency solidifies Nanostone’s reputation as a trusted leader across various industries.

Service & Support Experts

Service & Support Experts

At Nanostone, our commitment to excellence goes beyond providing cutting-edge water treatment technology. We believe in working closely with our clients, fostering a collaborative environment to ensure every project meets your unique needs and expectations. Our team continuously monitors the performance of your water treatment systems, using advanced metrics to ensure optimal functionality and efficiency. We stand by our products and services with long-term commitments and comprehensive warranty management, giving you peace of mind and reliable support throughout the lifecycle of your water treatment plant. Our ultimate goal is to make every plant using our membranes a resounding success, delivering reliable and robust water treatment solutions that stand the test of time.

Water Solutions for Municipalities and Industries

Nanostone’s cutting-edge ceramic membrane technology provides scalable, sustainable water treatment solutions for both municipal and industrial applications

Municipal Water Treatment

Efficient Water Treatment for Communities

Nanostone provides advanced ceramic membrane solutions to address the increasing challenges in municipal water treatment. Their technology ensures higher efficiency in removing suspended solids and contaminants, offering reliable, cost-effective, and scalable solutions to municipalities struggling with water shortages and quality issues.

Industrial Water Treatment

Reliable Filtration for Industrial Applications

Nanostone transforms industrial wastewater management by converting waste into a valuable resource. They focus on process water for efficiency, sustainability, and cost-effectiveness. Their global expertise allows tailored water treatment solutions, improving operations in areas like boiler feed water and cooling tower blowdown.

Applications

Discover Our Sweet Spot Applications for Water Treatment

From municipal to industrial needs, Nanostone provides advanced water filtration systems that ensure clean water, boosting efficiency and sustainability. See how we can enhance your water infrastructure with precision and reliability.

Proof of Excellence:

Explore Our Innovative Water Treatment Applications!

We understand the importance of finding the perfect fit for your unique water treatment needs and avoiding the pitfalls of empty promises. That’s why we invite you to explore our track record of success and discover the specific circumstances where Nanostone excels as a leader in water treatment solutions—and importantly, where we do not.

Complete the form below to schedule a session with one of our experts. You’ll quickly connect with someone who is deeply knowledgeable about your application needs and ready to help you navigate the possibilities Nanostone can offer—and honestly inform you when we might not be the best fit. Experience clarity, proven results, and efficient use of your time with us!

Testimonials & Certifications

Certified Excellence and Industry Recognition in Water Technology

At Nanostone, our leadership in water treatment is reinforced by globally recognized certifications that reflect our commitment to quality, innovation, and reliability. These certifications validate that our ceramic membrane technology meets the highest industry standards, delivering sustainable and effective solutions for municipalities and industries worldwide.

Certifications