Product Design

Factors influencing design

Creating an optimum design for challenging water streams

Nanostone Water has been at the forefront of ceramic membrane technology from its inception, and we take pride in our innovative approach to product development. Not accepting the constraints of performance from traditional tubular designs, our R&D scientists combined both ceramic and polymer science to create a unique, patented design for our segmented monolith module.

We made some very intentional product design decisions through the years, always focusing on how we could ultimately improve both performance and lifecycle costs for our clients. A few of the more notable developments appear below.

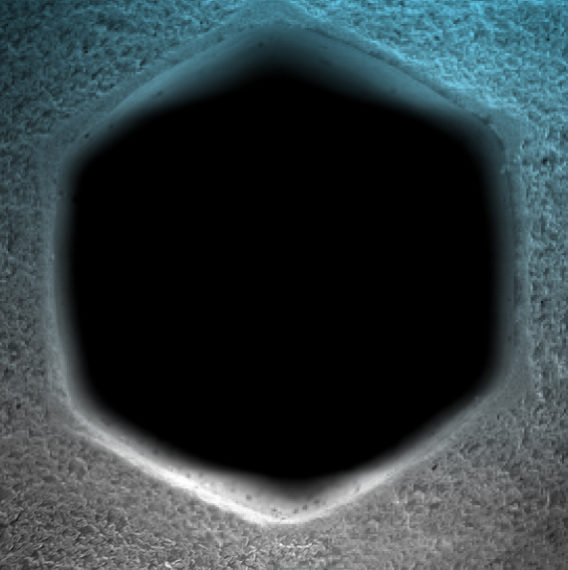

Improve the ability to handle high solids without high degree of fouling

Channels evenly distribute flow evenly during operation and backwash cycles to prevent fouling, which the team verified using computational fluid dynamics and numerous trials.

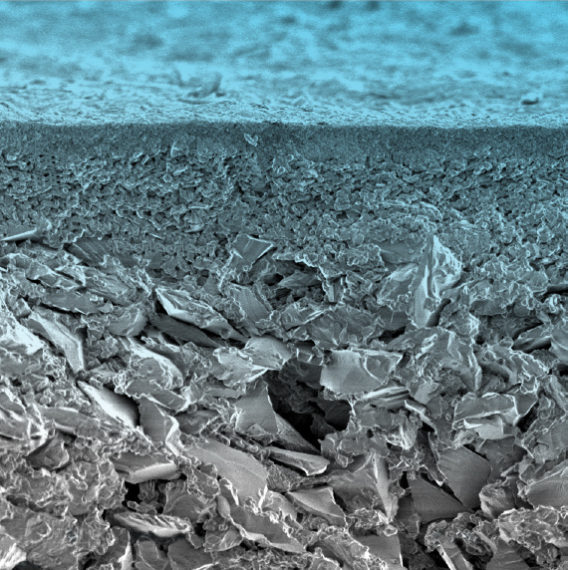

Improve the ability to handle high variability in water quality parameters

Our nanoparticle coating can achieve consistent filtration during abnormal operating conditions without sacrificing permeability through maintaining a right pore size distribution.

Improve the ease and cost of installation and maintenance

Standard UF configuration allows for easy adaptation to universal rack design configuration.

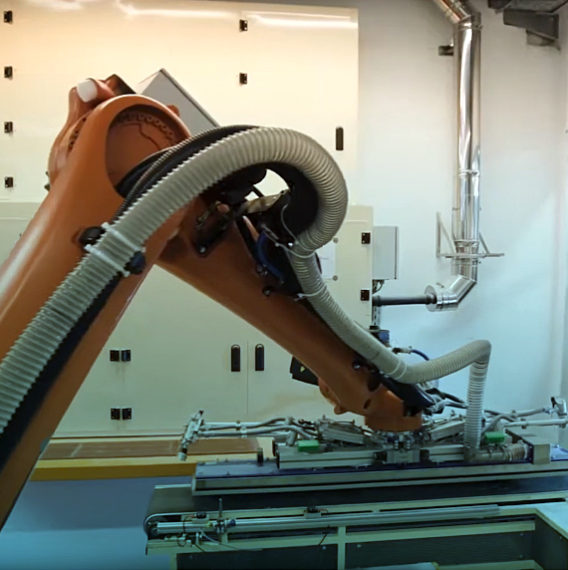

Drive manufacturing at scale for the high-performance product

Once thought of as cost prohibitive, our product design is robust and cost effective. Additionally, the highly automated manufacturing process in our factory enables us to meet the growing demand of our customers.